How much is 15% of your current labor bill? Would you like to cut that cost with happier employees?

by Joe Mikes

Picture yourself at a burger joint, first in line at the counter, watching them prepare the fries. How far is the salt from the loose French fries? How far are the containers from the fries? How many hands does it take to get a container ready to load? How does every employee line up the fries vertically in the container?

There is a reason for that. The management understands Value-Added vs Non-Value-Added activities. Most of the Fortune 500 level companies around the world have already studied and deployed Value-Added vs Non-Value-Added work into their positions. How many positions in our cannabis companies have we designed as well as the fry-line position?

When highly skilled consultants meet a company that has not rolled out this concept, they can easily save 25-35 % in labor costs. This is done by finding and removing operational wastes while embracing best practices. When a project like this is initiated, our current employees need to be embraced from the beginning. Everyone who wants to continue to work for us, gets to stay.

This should never result in pink slips, it should be an opportunity to get Operational Excellence rolling in our companies with the people we free up. It is also fair to expect that a new position or two may be required to run most effectively over the long term. If staffing is high after the changes are complete, initiate a hiring freeze. Company growth and or attrition will solve this financial complication soon enough.

Doing this ourselves or with hired experts, the employees need to know they are secure in their jobs if they do what is expected. Announce before you start this process that, “Some positions may be consolidated and some positions may be newly designed, regardless, there will be no layoffs. We will find a place for everyone that wants to work here and help this company grow.”

What exactly are Value-Added vs Non-Value-Added tasks within a job position? Value-Added tasks are simply those that the customer would be willing to pay for. Most of the time, the customers are internal until the service or product is sold at retail. With some basic lessons we can learn to do this without consultants. If we only get half of what a trained consultant would get, 12-15 % of our current labor bill could be diverted to more value-added activity for us to utilize and eventually those dollars to the bottom line.

Here is an example: What do our customers really want or what is value added for them? They want flower, concentrate, or another product at a weight, flavor, and potency agreed upon. Do they want to pay for labeling the packages, walking around the store selecting products, reloading the tape in the register, or cashiers monitoring the cooler temperature with edible products? No.

The first “internal customer,” or worker to be considered is the cashier. Think about what the cashiers really want. They want packages clearly labeled, weighed, and sealed without obstructions. They need these in sufficient quantity. They also want their equipment to run flawlessly. They are conducting value-added activities when they are working with clients, understanding their needs and selling them products.

The non-value-added activities include everything else: changing tape in the register, standing and waiting, fixing the label machine, fixing signage or other in-shop features requiring attention. The time spent applying the regulatory labels on the final packages is a non-value-added task, but still required to perform by law. Regulatory labeling is a great example that some non-value-added activities can NOT be eliminated.

Next, the product flow goes back to Packaging. What about the employees in the packaging department? What do they need for their jobs? Getting the correct cured flower at the right humidity, receiving the correct concentrates from the process center, items from the kitchen, and delivery of vendor products. They also need all of their retail packing supplies in adequate quantity, scales, and a clean space to work in.

Everything else conducted in packaging is non-value-added. For example; collecting supplies to do their work, searching for the best scale to use, unplanned breaks, waiting for a boss or another employee to get started, or recording the manifest data and weight for regulatory records all add no value. None of these activities are value-added but happen every day in every packaging area in every cannabis business; some of these required by law, but most are primarily due the original design of each position.

The chain of “internal customers” goes all the way back to the farm or cultivation facility, back to the position tagging seedlings and preparing soil. This entire chain of internal customers needs to be reviewed.

Non-value-added activities change position by position. Conducting this assessment requires more of a manpower effort vs a capital investment for the long-term financial benefits. To help clarify what the non-value activities might look like, there is something called the 7 Operational Wastes. Industrial engineers observing operations in all industries have identified these common labor wastes.

The non-value-added tasks typically fall into one the 7 Operational Wastes. These “wastes’ of effort” cause added expense and risk: They are Overproduction, Delay, Extra Inventory, Processing, Transportation, Wasted Motion, and Making Defects. These operational wastes eat away at profits and employee satisfaction. It is our responsibility as management to identify the wastes in each position and eliminate or reduce them.

Advantages of Value-Added vs Non-Value-Added Business Evaluation

1. Managers who cut barriers for employees, build mutual respect

2. Companies maximize the value that each employee brings each shift

3. Managers hire only the number of employees required

4. Employee expectations are much clearer

5. 80% of info needed for job descriptions is done

6. Identifying the value-added product or service from each “internal customer” simultaneously identifies the most critical items to measure for continuous improvement at the same time!

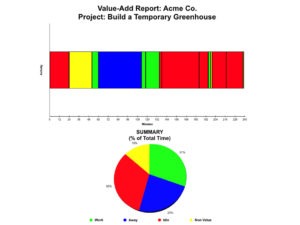

Individual positions, as well as a whole team project, can also be observed. The following graphs illustrate a team of 5 building a temporary greenhouse. In the chart GREEN is good. The green areas represent what you thought your employees would be doing most of the time. All the other colors are non-value-added activities. The linear chart shows the activities chronologically. The pie chart shows the sum of a four-hour study. Imagine the possibilities of reducing operational waste and maximizing your employees time on the job!

As you can see, there was a lot of time spent on other things. In fact 69% of the time spent was involved non-value-added activities. Understanding the details of everything that is not green, will reveal the operational waste that occurred during the event. Stop for a second and imagine the expense of this kind of detail per every position throughout your business. Research the 7 wastes on the internet. Many publications explain them, find more than one author to recognize subtle differences. With a modest effort, we can reduce obvious wastes and get a 15% reduction in payroll, this is very achievable.

Joe Mikes is an author and trainer in areas of Operational Excellence and a member of AMP: Association of Asset Management Professionals. He is available for more info at operationalreliability1@gmail.com.

References:

USC Consulting Group, USCCG.COM

Contact: Joe Politoske Sr VP

AMP: reliabilityweb.com